The 6-Minute Rule for Geotechnical Engineering For Construction Projects

The 6-Minute Rule for Geotechnical Engineering For Construction Projects

Blog Article

The Buzz on Geotechnical Engineering For Construction Projects

Table of ContentsGeotechnical Engineering For Construction Projects Can Be Fun For EveryoneGeotechnical Engineering For Construction Projects Can Be Fun For AnyoneHow Geotechnical Engineering For Construction Projects can Save You Time, Stress, and Money.Things about Geotechnical Engineering For Construction ProjectsSome Ideas on Geotechnical Engineering For Construction Projects You Should Know

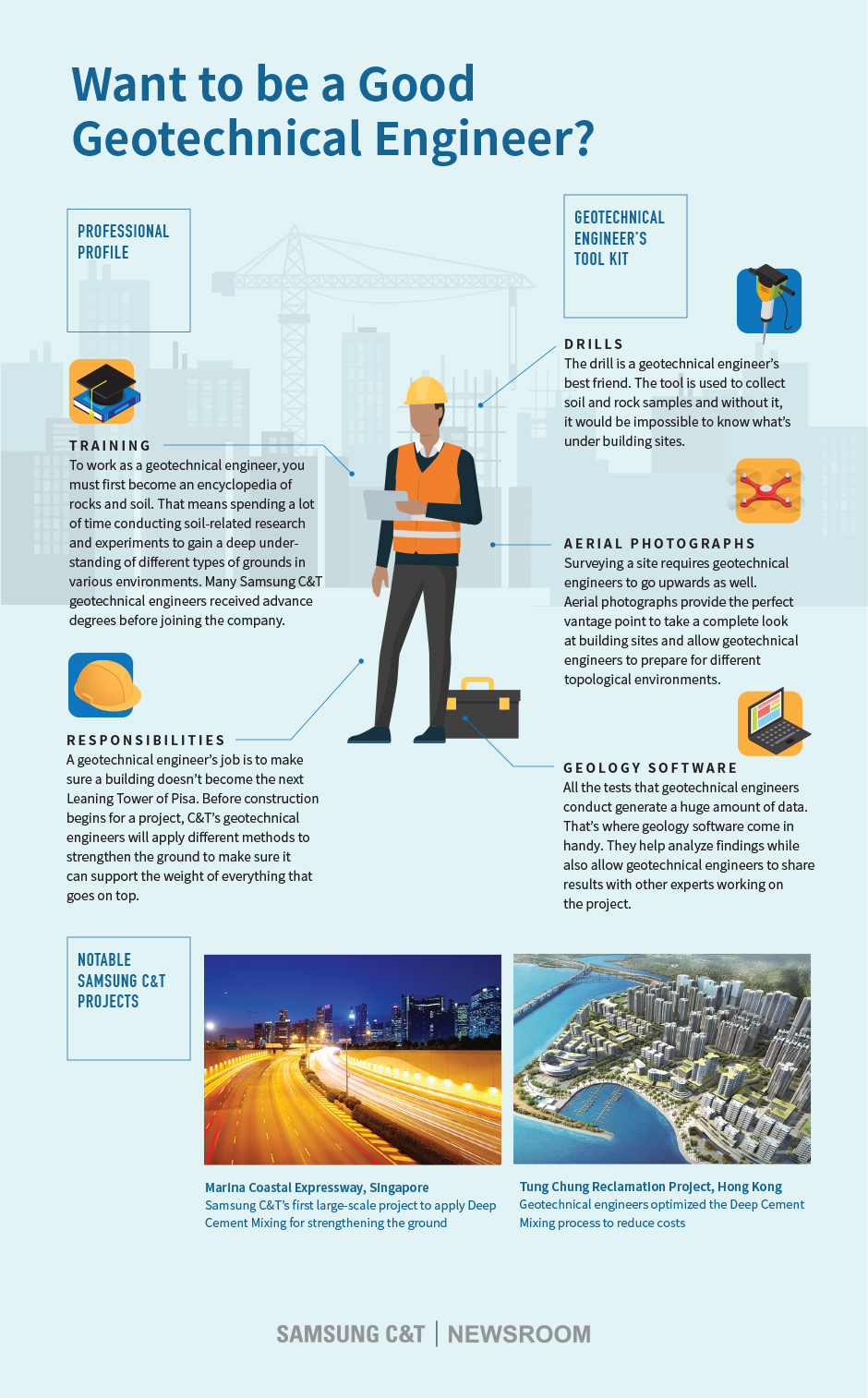

Throughout the investigation, it is important to drill at the called for deepness and the required number of openings as per the recommendation of the Canadian Structure Layout criterion. Often, the proprietor may save some Geotechnical Investigation price however wind up investing even more than the prepared for throughout the construction price.The responsibilities of the geotechnical specialist include giving material screening for building support. Geotechnical Engineering for Construction Projects. Geotechnical designers analyse all the area examination reports to make sure that building is going on as per the job requirements. During building and construction, a confirmatory test for soil compaction is done on-site to ensure that no future settlement takes place

After the concrete is poured -7 days and 28 days- tests are carried out on concrete samples collected from the website to ensure that the concrete poured satisfies the design standard. Asphalt core is taken after the Asphalt is laid and compacted to confirm that it meets the layout criterion. All research laboratory test records are evaluated by the Geotechnical Engineer to make sure that it satisfies the task specification.

Examine This Report on Geotechnical Engineering For Construction Projects

Geotechnical design plays a crucial function in ensuring the stability of building jobs. Learn how it affects style and overall project success. Geotechnical design is an essential branch of civil engineering that concentrates on comprehending the behaviour of planet materials, such as dirt and rock. It entails analysing subsurface conditions to make sure that a structure's structure or facilities is stable and safe.

For a reputable structure and a smooth building procedure, count on to offer the know-how you require. Call to obtain expert advice and geotechnical services tailored to your next project.

An Unbiased View of Geotechnical Engineering For Construction Projects

When starting a land advancement project, understanding the ground beneath your feet is as critical as the frameworks you intend to build above it. Our Geotechnical Engineering group analyse the ground, ensuring it is appropriate for the recommended growth while providing you with the information called for to fulfill your job goals.

Geotechnical Engineering checks out the formation of the ground, as it is the foundation for all tasks. Where frameworks require to be created relative to the ground conditions; ground problems (e.g., soft ground) might require strengthening depending upon the dimension of the desired structure. Before structure, you require to find out about the groundwater, dirt framework, and liquefaction chance of your land.

For sites that are not connected on the regional authority facilities extra site examinations would certainly be called for to offer technological inputs for on-site stormwater and wastewater. We have experienced Geotechnical Engineers based in each workplace, sustaining your geotechnical demands nationwide. Reach out to us to talk about how we can support your following project.

These records are tailored to fulfill the particular needs of a project and consist of layout parameters and advice for the building and construction of a series of manufactured structures. As giving working as a consultant services covering areas such as slope stability and load-bearing capabilities for basics different materials, these designers undertake research and growth tasks to improve techniques, tools, materials knowledge and great site analysis covering whole lifecycles.

Little Known Facts About Geotechnical Engineering For Construction Projects.

Nonetheless, rates of pay generally raise as your expertise and skills grow, with standards indicating a graduate beginning income of in between 18,000 and 28,000 per year in the UK. This rises to 26,000 to 36,000 with a few years of experience and after that getting to 40,000 to 60,000+ for elderly, chartered or master designers.

With the right application it is possible to master the profession and gain entry to a challenging yet fulfilling and important job. A rock hound would certainly need to re-train to become a geotechnical engineer, although there is lots of cross-over in between the 2 careers, which can make this less complicated - Geotechnical Engineering for Construction Projects. Geologists need to have an understanding of soils, rocks and various other materials from a scientific point of view, while geotechnical designers story their understanding of matters such as soil and rock auto mechanic, geophysics and hydrology and apply them to design and ecological tasks

When starting out, these engineers will have a tendency to deal with less complicated jobs, developing expertise and experience prepared for more challenging work later on. Geotechnical engineers often tend to specialise in certain locations as they grow in experience, concentrating on particular facilities such as trains, roadways or water. These designers also collaborate with renewable resource, offshore and onshore oil and gas, nuclear power, and much more.

Unknown Facts About Geotechnical Engineering For Construction Projects

The time taken to become a geotechnical engineer depends on where you are based, where you research study and what level of education you desire to obtain before getting in the office. Generally-speaking it takes 3-4 years to reach the fundamental requirements to begin a profession as a geotechnical engineer.

These procedures make it possible for professionals to assess a host of soil mechanics consisting of weight, porosity, void-to-solid particle ratio, leaks in the structure, compressibility, optimum shear check here toughness, birthing capability and contortions. If the framework needs a deep foundation, engineers will certainly use a cone penetration test to approximate the amount of skin and end bearing resistance in the subsurface.

When analyzing a slope's equilibrium of shear stress and anxiety and shear toughness, or its ability to withstand and undertake movement, rotational slides and translational slides are typically taken into consideration. Rotational slides fail along a rounded surface, with translational slides occurring on a planar surface area. An expert's objective is to identify the conditions at which an incline failure might happen.

Commonly, findings recommend that a site's dirt must be dealt with to enhance its shear strength, tightness and permeability before style and building. When it comes time to outline structure strategies, experts are increasingly concentrated on sustainability, even more specifically exactly how to minimize a structure's carbon impact. One technique has been to replace 20 percent of a structure's cement with fly ash, a waste item from coal fire nuclear power plant.

Report this page